Emerging Market Marine Engineering Consultancy

Deep reach technology

Deep Reach Technology

is the world’s leading specialist

Ocean Engineering consultancy

Specialist ocean engineering

An offshore engineering consultancy built on world-class engineering talent

We specialize in solving the most difficult offshore engineering problems.

Our team has decades of experience in offshore engineering, including deep-sea mining, developing and patenting novel anchoring solutions, and advising operators in offshore wind

Mission Statement

To empower the sustainable development of marine resources by delivering innovative, independent, and cost-effective engineering solutions for the world’s most complex offshore challenges—enabling our clients to lead in deep-sea mining, offshore wind, and marine infrastructure while upholding the highest standards of technical excellence and environmental responsibility.

Vision Statement

To be the global leader in offshore engineering consultancy, pioneering transformative technologies and practices that shape a cleaner, more resource-efficient future for the world’s oceans and energy systems.

Expertise

Our team has decades of experience in specialist offshore engineering

Deep-Sea Mining

We have over 50 years of experience in deep-sea mining, working with all the major contractors and license holders. Our work has included initial feasibility studies, development plans, and offshore system concept designs.

Offshore Wind

We provide technical analysis and business development to novel offshore wind concepts, including concept evaluation, technical feasibility, economic analysis, and prototype test development.

Oil & Gas

Our expertise spans all aspects of developing offshore oil and gas installations, including floating production systems, spars and tension-leg platforms. Highlights include doing the original architecture work on the first Spar concept.

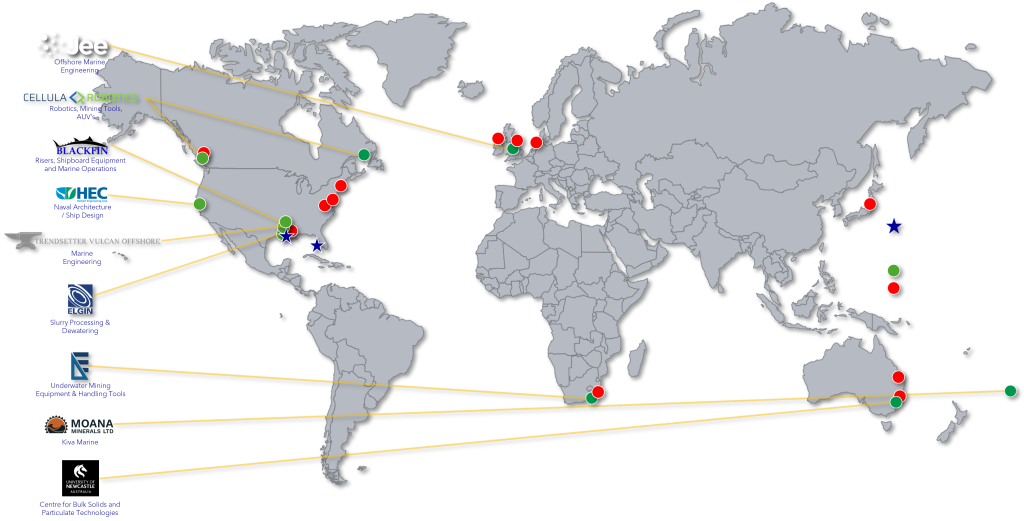

Clients

We work with tier-one Operators, License-Holders and Institutions

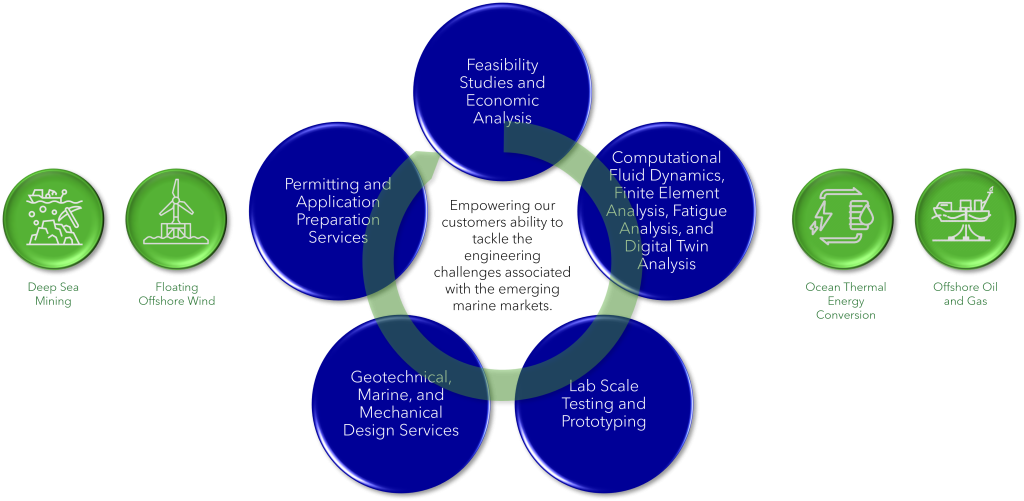

Services

Drillship Conversion

Concept Design and Cost Estimating for DGs SEC Report (via AMC Consulting™) Upgraded Vittoria 10,000 Pilot Test (Allseas™) to small commercial system. Further upgrade to large commercial system after 5-years operation Transport simulation and cost estimates with limited buffer storage

Material Handling & Offloading

Offloading by slurry to a transport vessel in tandem with the mining vessel. Decanting is used in this example to dewater ore in buffer tank. Problem is how to remove nodules from hold of mining vessel and create slurry for transfer. Shown at left is a re-slurry pump.

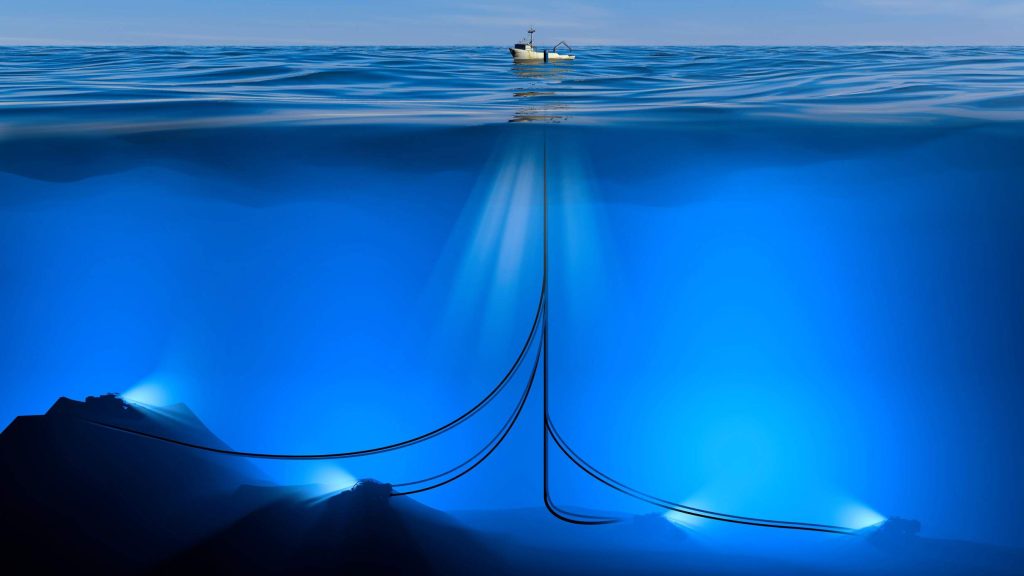

Subsea Collectors & Risers

Complete digital twin / quasi-static modeling with computation fluid dynamics, material fatigue analysis and finite element analysis via OrcaFlex™ Simulations to test sensitivity to collector position & varying operating conditions. Development of Feasibility and Techno-Commercial Models related to the design, build and deployment of systems given the extreme environmental conditions.

Conceptual / Detailed Design & Testing

DRT can provide complete project engagement from conceptual designs to techno-economic feasibilities to full detailed design. Systems may include collector systems, risers, offloading systems, re-slurrification systems, pressure let-down systems, and material storage systems.

Mooring Design

Mooring systems are key components of a floating offshore wind farm as they ensure maintaining floating offshore platforms within a targeted area. DRT provides innovative floating offshore wind engineering and design services for the most popular platforms in the market today, including Barge, Semi-Submersible, SPAR & Tension Leg Platform-type.

Hydrodynamic Modeling and Mooring Analysis

DRT’s modeling specialists have extensive experience in deploying OrcaFlex allowing for dynamic analyses of offshore marine systems and modeling mooring systems of floating offshore wind turbines. Mooring systems optimization requires comprehension of the phenomenon driving and influencing the design.

Interface Mooring and Structure

DRT provides specialized design and analysis support for concrete connection structures for WindCrete and ActiveFloat designs to de-risk deployment. Connections are critical to any new design, as they tend to be rigid, and require careful assessment with concrete floaters with the moorings to assure design performance.

Subsea Geotechnical

Our team has developed unique expertise in downhole rock and soil sensor systems, analysis of in situ geotechnical data, general characterization of rock and soil strength. By carefully understanding the geotechnical aspects of the target geology, de-risking of the project is achieved.

Case studies

Deep-Sea Mining Digital Twin

Our client was developing a complex offshore deep-sea mining concept, which integrated various new and innovative systems and technologies.

We developed a digital twin of these integrated systems, including a full physics engine and offshore dynamics. System components that we integrated into the model included a production support vessel, offshore supply vessels, subsea harvesters, and a riser system.

This allowed us to optimize engineering and operational parameters, whilst allowing the client to clearly illustrate their proposed concept to partners and investors.

Deep-Sea Mining Development Plan

For The Metals Company’s successful 2021 IPO, Deep Reach Technology was the Qualified Person tasked with developing the offshore development plan and mining systems concept.

SEC requirements for mining companies include stringent disclosure requirements around mineral resources and operations. We are one of the only companies in the world with sufficient expertise and experience in deep-sea mining to be classified as a Qualified Person and be able to do this work.

Decades of experience in deep-sea mining planning, modelling, and real-life operations meant that we developed a comprehensive and accurate mine development plan, offshore system concept and various staged development systems for production support vessels. This was a core component of the technical plan that lead to a successful fundraise.

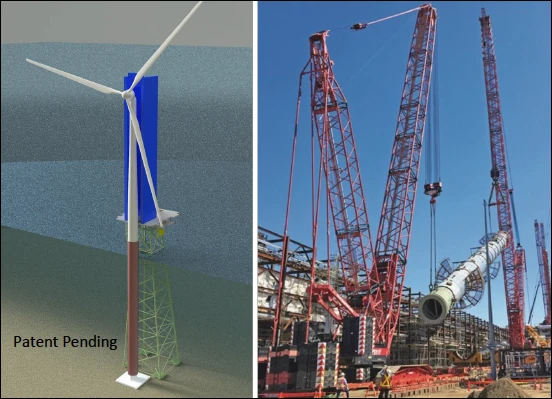

Offshore Wind Innovation for NOWRDC

As part of a project sponsored by National Offshore Wind Research and Development Consortium, we developed an innovative manufacturing and installation method for offshore floating wind farms.

Offshore floating wind is growing rapidly, and hundreds of floating substructures are required to support the vast number of turbines that will be installed. Manufacture and installation of huge offshore wind turbines is challenging, and new solutions are needed to meet this need.

Drawing on our expertise from other offshore engineering projects, including spar installation in offshore oil & gas projects, we proposed and are developing a new method for offshore manufacture of spar or buoyant tower wind turbines. This concept has the capacity to produce and install around 50 offshore wind turbines per year, for around 30-40% lower CapEx than current methods.

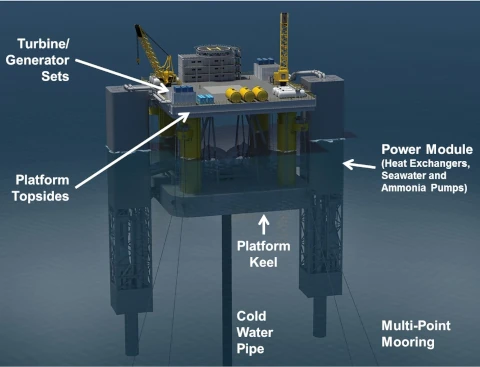

OTEC Concept Design & Evaluation

Offshore Thermal Energy Conversion is a renewable power generation concept that has been researched since the 1970s. It produces energy by harnessing the thermal gradient between warm surface waters and cold deep ocean waters at a depth of approximately 1000m.

We provided deep technical expertise around concept design, modelling and techno-economic analysis for an offshore floating OTEC project sponsored by Lockheed Martin and the Department of Energy.

In particular, we brought expertise in dynamic modelling of complex offshore structures, along with physical prototype testing, which allowed for hydrodynamic testing and load analysis of this unique structure.

Team

A team of world-leading offshore engineers, scientists and innovators

Dr. John Halkyard, PE

50+ years leading deep sea development projects. Ten years heading Kennecott’s nodule mining system development; 30 years in oil & gas R&D. Co-inventor of successful Spar platform. Technical lead on OTEC Platform Development as consultant to Lockheed-Martin. Visiting Professor National University of Singapore, 2008 – 2014, initiated graduate course in floating system design and analysis, moorings and risers.

Founded Deep Reach Technology in 2011 & Ocean Minerals LLC in 2015.

BS Purdue, Ocean Engineering; ScD MIT, Ocean Engineering. Life Fellow ASME and SNAME

Michael Rai Anderson, PE

25+ years in project and executive management roles in the energy services and engineer-to-order (“ETO”) business. Experience includes CTO of TerraSource Global, ETO of specialty mining, minerals and O&G technology; President of Elgin Separation Solutions, ETO for dewatering and liquid / solid separation technologies; Vice President of T-3 Energy, an ETO of oil-field pressure control solutions; and Senior Project Manager for CDM Smith’s Environmental Services Division.

Joined DRT Board in 2014.

BS Columbia University, Chemical Engineering; BA Carroll College, Applied Mathematics & Chemistry

Steven Rizea, PE

20+ years design and numerical hydro-thermal modeling of offshore renewable and deep-sea mining systems. Sr. Mechanical Engineer at Makai Ocean Engineering including Ocean Thermal Energy Conversion (OTEC) design and modelling. Joined DRT in 2017, developed and validated airlift simulation. Led DOE and ARPE-E projects including nodule collector with plume mitigation.

Joined DRT in 2017.

BS U of Florida, Mechanical Engineering; MS, U of Central Florida, Mechanical Engineering

Jim Wodehouse, PE

40+ years’ experience in the execution of offshore O&G drilling and floating production projects, including cost estimating, proposals preparation, and concept engineering, through to the detailed design, procurement, contracting and construction for projects spanning $1.0 billion. GM and VP of Engineering of several engineering contractors. Currently project manager for major nodule collection environmental assessment and test project in Japan.

Joined DRT in 2017.

BS, U of Western Ontario, Mechanical Engineering; ME courses University of Calgary & U of British Columbia

Nanco Eelman

Successful Manager / Engineer with 34 years of international experience in the Energy sector, including 7 years in field operations and 27 years in business development and engineering management. Specialties in strategic and technical business development and product development to support organizations to grow and execute strategy, improve financial performance, build high-performing teams, and achieve team objectives.

Joined DRT in 2025.

Noorderhaaks University Mechanical Engineering Degree and North Park University BS Business and Marketing

Dr. Kamlesh Joshi

5 years of experience solving mechanical and aerospace engineering problems. Experienced in handling CFD, Thermal and Fluid dynamics-based projects with an ability to work on optimization of the system. Principle analyst on nodule collector plume mitigation project funded by ARPA-E. Modelled frow from seafloor to separator and riser of a deeps mining system.

Joined DRT in 2020.

Master of Technology, IIT Roorkee, Computational Fluid Mechanics; PhD, U of Central Florida, Experimental & Computational Fluid Dynamics.

Sanjana Das

4 years with DRT serving as project engineer on offshore designs, including subsea micropiles for floating wind applications. Graduate research using Immersed Boundary Finite Element Method (IBFEM) to solve contact problems.

Joined DRT in 2021.

BS, Manipal Institute of Technology, Aeronautical Engineering; MS, U of Florida, Mechanical Engineering.

Thomas Chafe

Prior to joining DRT in 2024, Process Engineering co-op student experience at Cenovus Energy conducting process simulations for the oil & natural gas industry of Newfoundland. Currently lead author for the process engineering section of a Scoping Study for the Japanese nodule project, working with Subject Matter Expert consultants in both hydro- and pyro-metallurgy for nodule processing.

Joined DRT in 2024.

BE, Memorial University of Newfoundland and Labrador, Process Engineering.

Mia Gaudet

Experience in autonomous surface vehicle design, research on classification requirements for structural guidance in design of arctic vessels and recently at DRT assisted in drafting a deep-sea mining scoping study for the University of Tokyo and specifications for environmental surveys and test mining including seabed conditions, metocean requirements and design basis. Intl

Joined DRT in 2024.

Baccalaureate, United World College, Changshu China; BE, Ocean and Naval Engineering, Memorial University, Newfoundland and Labrador.

Dr. Mohammed Uddin

Modeling simulation specialist. His expertise includes Hardwire-in-the-Loop simulation and setup, deep sea mining, bio-inspired engineering, subsea micro-pile design, rapid prototyping, and ship design/construction.

Joined DRT in 2021.

Ph.D., Ocean Engineering at Florida Atlantic University. M.Sc. In Marine Technology / Structural Engineering from Norwegian University of Science and Technology.

Dr. Robert Blevins

40 years experience as well know specialist and author in fluid dynamics and fluid-structure interaction. Author of – Flow-Induced Vibration, Formulas for Natural Frequency and Mode Shape, and Applied Fluid Dynamics Handbook.

Supporting DRT since 2019.

Ph.D, Applied Mechanics and Masters of Science, Mechanical Engineering, Caltech. Bachelor of Applied Science, Mechanical Engineering, Carnegie Mellon University Master of Business Administration, San Diego State University.

Dr. Fernando Frimm

40 years’ experience including leadership positions in Exmar Offshore, SBM Offshore and GustoMSC. Recently lead DRT effort to investigate drillship conversion for deep ocean mining.

Supporting DRT since 2019.

Massachusetts Institute of Technology Ph.D., Ocean Engineering

Jon Machin

35+ years experience in geotechnical engineering and subsea vehicle development. Helped develop first subsea drill for Perry Slingsby and was Head of Offshore Engineering for DeepGreen Metals (now The Metals Company) for 10 years.

Supporting DRT since 2011.

Masters in Engineering Science, University of Oxford

Diana Paulikas

20 years as multi-disciplinary team leader in aerospace, defense and deep-sea mining industries. Three years as Head of Sustainability Studies for the Metals Company. Currently lead author for the Scoping Study (JOC Standard) for the University of Tokyo nodule project.

Supporting DRT since 2024.

MBA, Government and Policy; International Economics Harvard & MSc; Econometrics; London School of Economics

David Felix

14-year geologist for KCON nodule project, 1968-1982. 7-years as mining consultant and 19 years as Technical Specialist.

Supporting DRT since 2011.

San Diego Department of Environmental Health.

Richard Petters

Project engineer for OMI nodule collector tested in 1978. 25 years designing and testing subsea equipment; ROVs, AUVs, trenchers, etc. Lockheed Martin Undersea Systems.

Supporting DRT since 2011.

University of Hawaii M.S. Ocean Engineering and Florida Atlantic University B.S. Ocean Engineering

Sharath Ravula

20 years of diversified engineering, oceanographic, and geotechnical experience in the academic and offshore industry, supporting engineering, and oil & gas clientele, including data processor, oceanographer, navigator, surveyor, and engineering positions for various field development surveys and platform installations.

Supporting DRT since 2014.

Columbia Engineering B.S., Mechanical Engineering and Texas A&M University M.S., Oceanography

John Buckell

20 years’ experience in all aspects of onshore and offshore Geotechnical operations, including the project management, QHSE, geological / geotechnical interpretation and engineering design. Responsibility for seabed investigations including ROV operated seabed drilling, sampling and in situ testing system and the geoROV seabed geotechnical system.

Supporting DRT since 2024.

Bangor University; BSc Hons, Ocean Science (Geology, Geotechnics, Marine Chemistry and Physical Oceanography)

Doug Maxwell

Experienced project manager for process testing, process design, feasibility studies and construction projects. Co-inventor of DRT’s shipboard process for recovering rare earth elements from seafloor sediments.

Supporting DRT since 2014.

Masters of Engineering, Metallurgy, Colorado School of Mines. Bachelors of Science, Metallurgical Engineering, Colorado School of Mines.